"shop-teacher" (shop-teacher)

"shop-teacher" (shop-teacher)

07/11/2017 at 21:19 ē Filed to: RallyMetro

2

2

24

24

"shop-teacher" (shop-teacher)

"shop-teacher" (shop-teacher)

07/11/2017 at 21:19 ē Filed to: RallyMetro |  2 2

|  24 24 |

Last month I found out what I had done !!!error: Indecipherable SUB-paragraph formatting!!! on the RallyMetro. The short version, for those who are not interested in clicking on the link, is one of the bolts holding the front left lower control arm backed out, causing the front end alignment to go radically wrong. I FUBARED the front left tire just towing it the 85 miles home.

I couldnít just get another bolt and install it, because the threades were totally jacked up. After pondering for a while about what to do, I decided I should drill and tap the hole for a bigger bolt. I dug through my tools and found a 5/8"-18 tap in a small box of taps that had been given to me by the official self-appointed RallyMetro body-man, FryGuy.

I scared up a grade 8, 5/8"-18 x 1-1/2" bolt at my local Fastenal store, and ordered a 37/64" drill bit from the ultranets. Grand total for these was something like $11.

The drill bit arrived yesterday, and today my girls were at daycare, so I figured Iíd spend the first hour or two of my morning knocking this repair out right quick. Drilling the hole out went nice and easy, because it really didnít need to be much bigger. Then good oleí Murphy starting kicking me right in the gentlemanís area.

My tap holder wasnít big enough for a 5/8" tap, but I found a 3/8" 8-point socket that came from the first socket set I bought when I was 13-years old (tool collecting pays off!) that would work. I then put some thread cutting oil on the tap, and turned it in a few cranks ... maybe a turn and a half total, probably not even that much. Then the tap jammed, so I went to back it out. It backed out a little, then it jammed. I tried back and forth several times, but to no avail.

Thinking perhaps it was the slop in my driving mechanism that was causing me trouble, I hopped on my scooter and hit the local Ace hardware and NAPA trying to find a proper tap holder. No dice there. I headed home and called my buddy who teaches machining and asked his advice. He said I was almost certainly jammed on a chip, and was simply going to need more leverage to get it out. His suggestion, ĎYour 8-point socket is probably a 3/8" drive, so put a 1/2" adapter and a breaker bar on it, and give it a good yank.í

Well, my socket was a 1/4" drive, so I put a 3/8" adapter and my favorite socket wrench on it, and gave it a nice big pull. Thatís when the Harbor Freight adapter snapped. At this point I was pissed off, so I put a socket adapter on my cordless impact gun and tried that. All that managed to do was put some wear marks in the socket itself.

I then headed to Lowes, as Iíve been happier with Kobalt than I have Craftsman tools recently. I wasnít able to find a 3/8" drive 8-point socket, so I bought a set of adapters hoping for better luck with a quality adapter. I checked for a proper size tap holder while I was there, but again had no luck.

Immediately upon my return home, I broke that adapter too. At least that one Iíll be able to exchange for a new one. Then I headed for Sears, hoping for either a bigger drive 8-point socket, or a proper sized tap holder. No luck on the socket, but I did find the correct tap holder. Also, I got it for 20% off.

Sidenote for Chicago-area Oppos: The Oakbrook Sears is having a remodeling sale. Most tools are 20% off right now. Theyíre still pretty well stocked.

Genuinely happy to now have to correct tool, I put it on and cranked as hard as I could ... and made absolutely no progress. I tried a bunch of times back and forth and got nothiní.

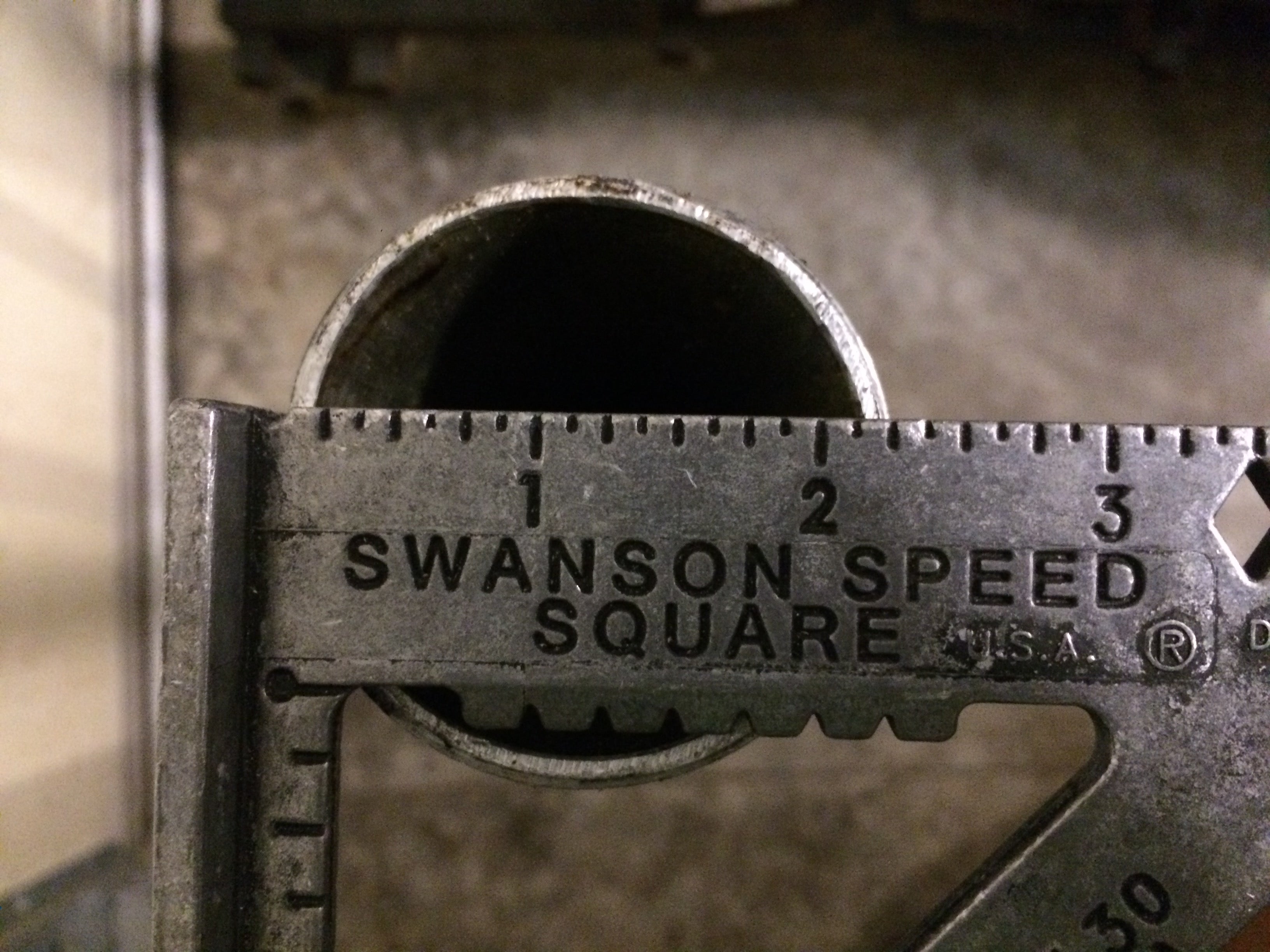

By then it was time to pick up the girls, so thatís how it sits right now. The only thing I can think to try tomorrow, is slide some bits of electrical conduit over the handles to make them longer and get more leverage. Any suggestions are welcome.

The best laid plans ...

My X-type is too a real Jaguar

> shop-teacher

My X-type is too a real Jaguar

> shop-teacher

07/11/2017 at 21:30 |

|

Last resort heat the metal.

shop-teacher

> My X-type is too a real Jaguar

shop-teacher

> My X-type is too a real Jaguar

07/11/2017 at 21:45 |

|

Good call.

OPPOsaurus WRX

> shop-teacher

OPPOsaurus WRX

> shop-teacher

07/11/2017 at 21:45 |

|

punch and kick it

XJDano

> shop-teacher

XJDano

> shop-teacher

07/11/2017 at 21:49 |

|

If you get electric conduit donít fuck around, get something big enough. Here is the one I use. I stole it out of the scrap pile and I think itís aluminum. EDIT: Magnet confirmed, itís not steel. Also you can remove the ball from the hitch and itíll work like the double box wrench thing, 90į angle though

Also Iím sure you can find something around the garage thatíll work.

Urambo Tauro

> shop-teacher

Urambo Tauro

> shop-teacher

07/11/2017 at 21:54 |

|

Earplugs. You need earplugs. Child-size ones.

Yíknow, so that you can apply as much cussing as you need to get that tap unstuck.

shop-teacher

> XJDano

shop-teacher

> XJDano

07/11/2017 at 21:55 |

|

Nice! Iíve got some laying around. Not quite that big, but hopefully big enough.

shop-teacher

> Urambo Tauro

shop-teacher

> Urambo Tauro

07/11/2017 at 21:56 |

|

I think my ears are calloused enough to handle it. I spent a lot of time on construction crews.

shop-teacher

> OPPOsaurus WRX

shop-teacher

> OPPOsaurus WRX

07/11/2017 at 21:56 |

|

Yes, good call.

XJDano

> shop-teacher

XJDano

> shop-teacher

07/11/2017 at 21:58 |

|

I thought you meant youíd buy some.

Iíve never had to drill and tap so thatís unfamiliar territory for me.

Full of the sound of the Gran Fury, signifying nothing.

> XJDano

Full of the sound of the Gran Fury, signifying nothing.

> XJDano

07/11/2017 at 22:07 |

|

Ages ago my dad told me a story of when he was a child, helping his dad do a head gasket replacement on the familyís Ď53 Chevy. He grabbed a lot looooooong pipe to use as a cheater bar so he could get plenty of leverage and then proceeded to snap off a head bolt in the block. Oh %*^$&...

shop-teacher

> XJDano

shop-teacher

> XJDano

07/11/2017 at 22:09 |

|

Nah, not if I can avoid buying more stuff.

shop-teacher

> Full of the sound of the Gran Fury, signifying nothing.

shop-teacher

> Full of the sound of the Gran Fury, signifying nothing.

07/11/2017 at 22:09 |

|

WHOOPS!

Urambo Tauro

> shop-teacher

Urambo Tauro

> shop-teacher

07/11/2017 at 22:11 |

|

Not for† your ears, silly!

Full of the sound of the Gran Fury, signifying nothing.

> shop-teacher

Full of the sound of the Gran Fury, signifying nothing.

> shop-teacher

07/11/2017 at 22:17 |

|

You only do that once. And thankfully I learned from his mistake.

I did, however, screw up a head gasket repair on my E21 decades ago by getting the timing wrong, as evidenced by the ď CLANK CLANK CLANKĒ as pistons met valves. Shit.

The damage wasnít too bad, and a couple of valves and some minor grinding of the dents in the pistons and everything was back to normal (but I failed to detect the cracked block that started acting up 3-4 years later...)

XJDano

> Full of the sound of the Gran Fury, signifying nothing.

XJDano

> Full of the sound of the Gran Fury, signifying nothing.

07/11/2017 at 22:27 |

|

shop-teacher

> Urambo Tauro

shop-teacher

> Urambo Tauro

07/11/2017 at 22:38 |

|

Gotcha. Kiddos will be at daycare again tomorrow.

EL_ULY

> shop-teacher

EL_ULY

> shop-teacher

07/11/2017 at 22:47 |

|

I need a tap and die and some WD 40!

-Hank Hill

Shoop

> EL_ULY

Shoop

> EL_ULY

07/12/2017 at 00:49 |

|

nonononoNoNoNoONNONONOOOOOO

WD40 is not a good lubricant for this or really at all.

Birddog

> shop-teacher

Birddog

> shop-teacher

07/12/2017 at 03:18 |

|

Have you ever been to The Tool Store in Stickney? Theyíre more of a Scooter and Go-cart shop now.†But,†I bet theyíd have the tap handle youíre looking for.

You could order the right tool online too.

shop-teacher

> Birddog

shop-teacher

> Birddog

07/12/2017 at 07:28 |

|

I havenít, but now I must go there. Sears had the tap handle, but I still canít get it out. Iím going to try extension handles on the tap handle and/or heat today. If that doesnít work, Iíll order a socket with a bigger drive.

MM54

> shop-teacher

MM54

> shop-teacher

07/12/2017 at 21:51 |

|

Once youíre able to back it out (going back and forth with it may help some to fatigue the chip), before trying to continue:

I have tapped many holes (hehe) and broken minimal taps.

Birddog

> shop-teacher

Birddog

> shop-teacher

07/13/2017 at 03:29 |

|

Dang! That thing is really stuck. Iíd be worried about breaking the tap at that point.

If you want to waste some time that place is a fun way to do it. He was the Harbor Freight of the area before HF existed.

shop-teacher

> MM54

shop-teacher

> MM54

07/13/2017 at 07:19 |

|

I was able to get it out and finished with regular cutting lube yesterday. Iíll pick some of that up before I tackle another project like this.

shop-teacher

> Birddog

shop-teacher

> Birddog

07/13/2017 at 07:46 |

|

I was worried about breaking the tap. The craziest thing happened yesterday though. I cut some extension handles out of a scrap piece of conduit. I climbed under the car, touched the tap handle.... and the tap fell out.

I got the hole tapped and the bolt installed within an hour.